Lets Talk Materials

Like, really get into it, this page isn't going to be for the faint of heart.

Exploring Some Material Science

Much of the inspiration for Morning Cup Leather comes from a commitment to highlighting the high-quality materials we use and the incredible properties they possess. Check out the tabs below for a deep dive into why we use what we do and how much of the hand-crafting process is more important than you might expect.

What is Leather?

That may sound like a silly place to start but we think that most people's understanding of it is as a luxury material, only useful in incredibly high-end bags and fancy car upholstery.

It's important to remember that humans have been tanning and using it for many thousands of years, with the first leatherworking tools being dated back to 5,000 BC (although evidence of tanned leather can be traced back over 400,000 years). At this point, it was used to build shelters and shoes, although during the bronze age, this was expanded into shields and armor, illustrating the versatility of the material. The Romans expanded this into belts, saddles, and other straps while in Egypt, they were already using to craft jewelry and bags.

In all of these cases, we see leather highlighted, not just as a textile for the wealthy, but as a substance with a myriad of properties allowing it to act like silk or steel depending on the need.

Okay sure, but what IS it?

Leather is the tanned hide of basically any animal. You can make leather from the hides of alligators, ostriches, and even stingrays. For our purposes, however, we'll be taking a look at the most common type - cow leather. When an animal is skinned, the fibers of the hide are raw (hence "rawhide" if you've heard the term before). The process of tanning converts these fibers into a permanently stable form, ensuring that they are no longer able to rot.

The term tanning comes from the tannins used in the process (although actually, it's technically the other way around, the etymological origin of tanning is a Celtic word for tree, go figure), compounds found naturally in almost all vegetable matter. Tannins are what cause tea leaves to darken water when you steep them. They're also responsible for the 'tannic' or drying taste of things like over-steeped tea or a glass of dry wine (this experience is the feeling of the tannins binding with the proteins on your tongue and VERY slightly tanning it, just as they would leather, freaky!). The tannic compounds from tree bark and other vegetal sources are extracted and applied to the raw hides in large vats where these compounds bind to the proteins in the rawhide fibers, forming a semipermeable layer that prevents decay and causes the hide to officially become leather. More specifically, the fibers become resistant to the hydrolysis of bacteria that cause putrefaction This process takes about six weeks to complete. There are several other types of tanning but all the leather we use is vegetable tanned. It takes the longest but it's also the best for the environment.

Unique Properties

Leather (specifically vegetable tanned for this conversation) has a handful of physical properties that make it an incredibly unique material. First of all, at a normal temperature and humidity, it's an almost entirely elastic material. Even if it may not seem like it, leather stretched along a single axis (before failure) will eventually return to its original shape. Since it is a fiber-based material, it does this along all axes. The caveat to this is that if heat and/or moisture is applied, any deformation can become plastic, meaning if you soak leather and apply heat before and during any kind of deformation, this will permanently shape and mold the leather. This is why you can so successfully make things like gun holsters, knife sheathes, and briefcases.

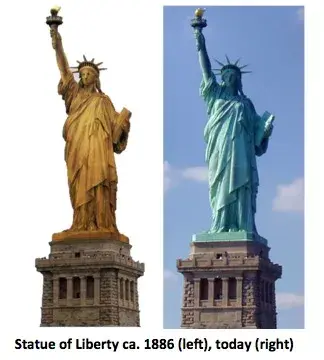

Additionally, vegetable-tanned leather generally has waxes and oils that are impregnated into it during the tanning process, making it highly water resistant despite being entirely naturally derived. It also, unlike chrome-tanning (a chemical tanning process using chromium salts), will continue to darken with handling and sun exposure, leading to unique patinas that increase its water resistance, strength, and aesthetic appeal over time.

Chart illustrating the comparative Moduli of Plasticity for different materials. Note that leather's is significantly higher than vinyl and polyurethane, despite being the only natural material tested. (G. Lewis, 2003)